Project Overview

I joined the SDSU Rocket Project as an Avionics team member, contributing to the design and manufacturing of ground systems equipment. Unfortunately, due to team dynamics and project direction changes, my contributions did not culminate in any completed projects. The lack of motivation created from scrapping of all my projects led me to eventually step away from the team.

However, the hands on experience I gained in 3D modeling, hardware integration, data acquisition systems, and teamwork has been invaluable for my growth as an engineer.

Key Contributions

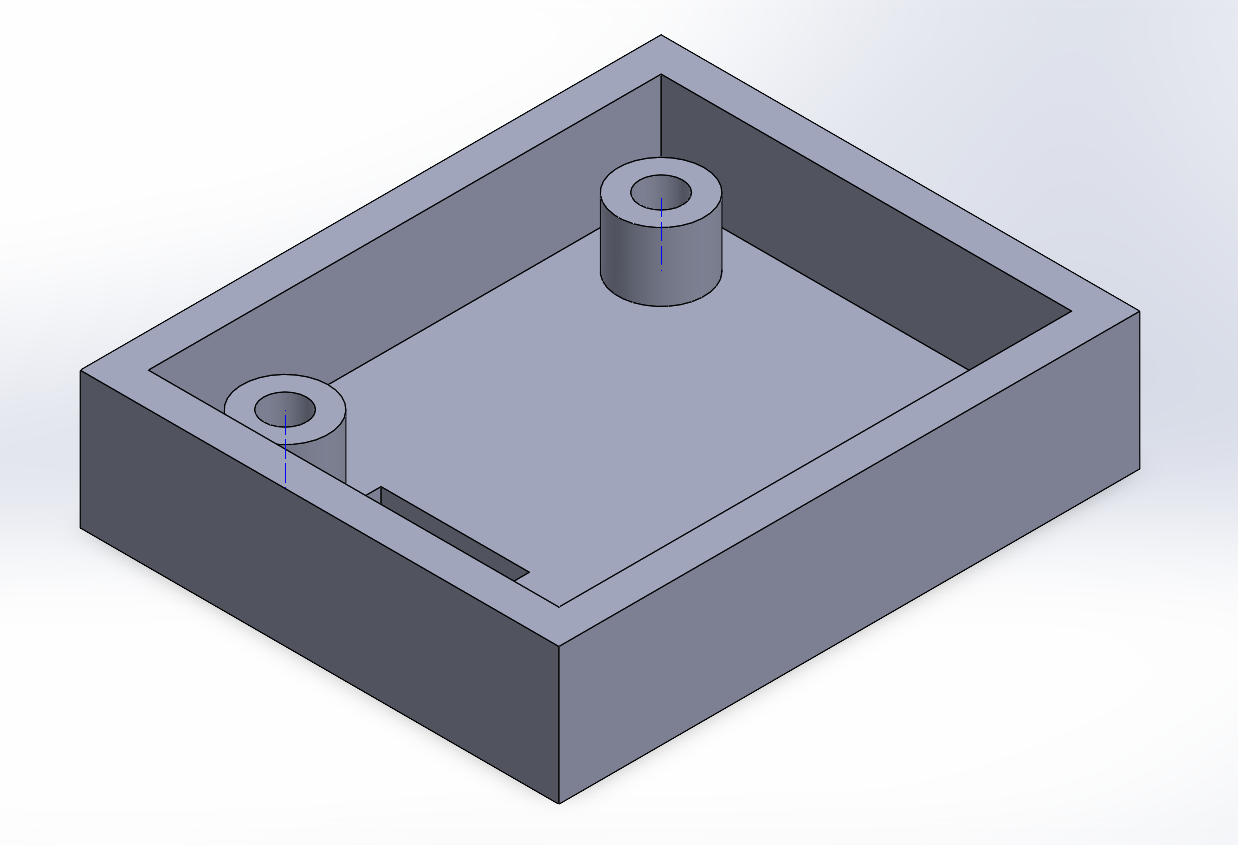

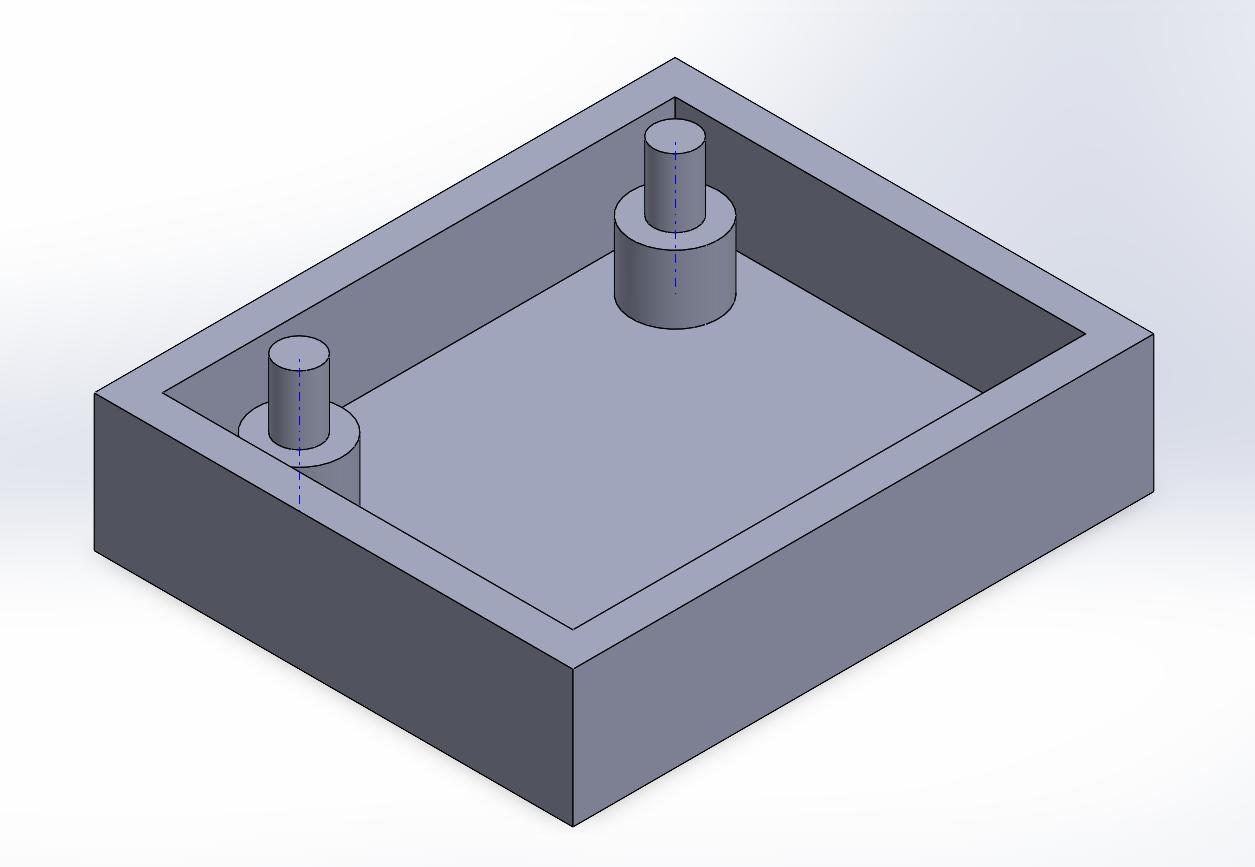

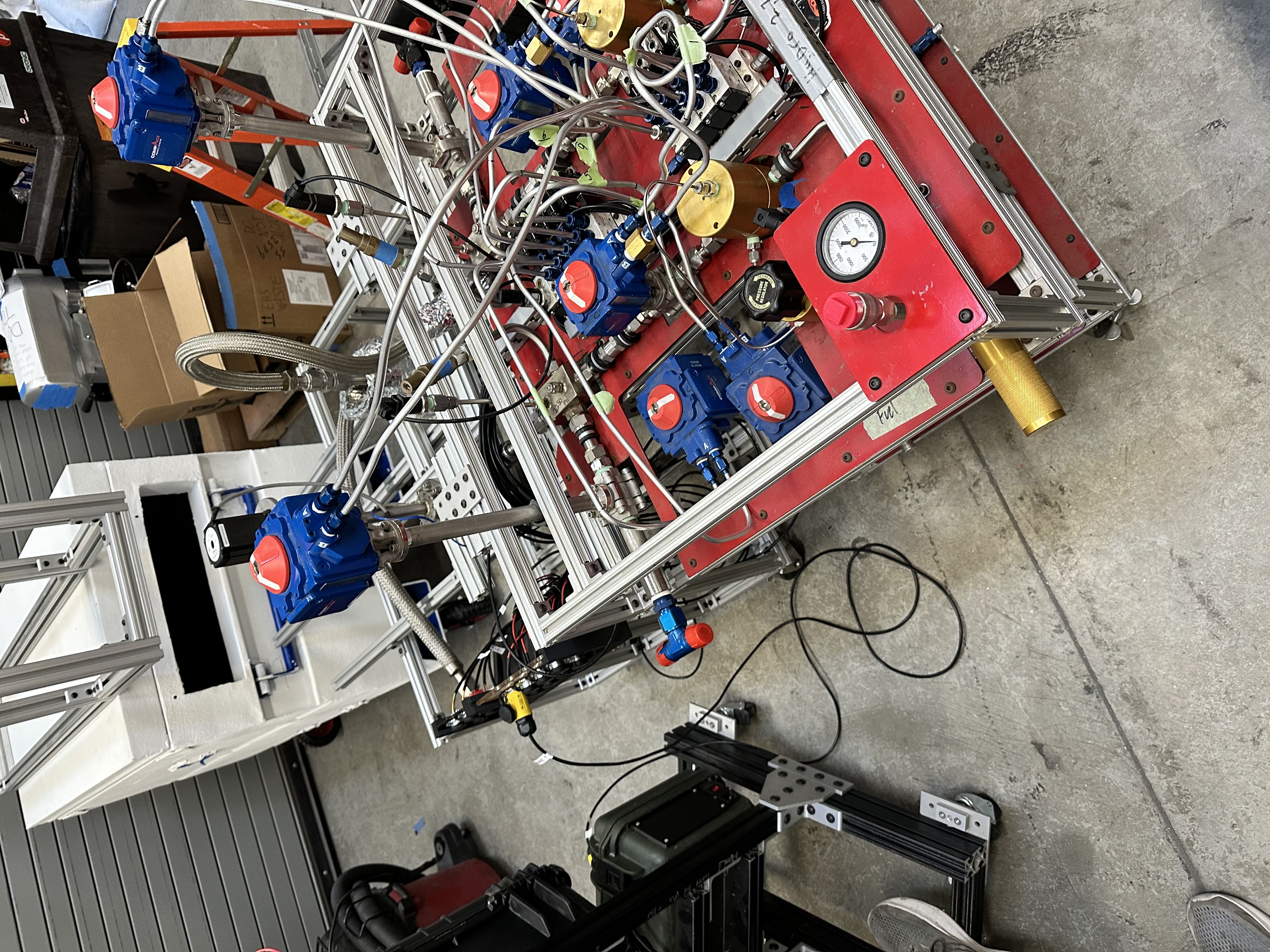

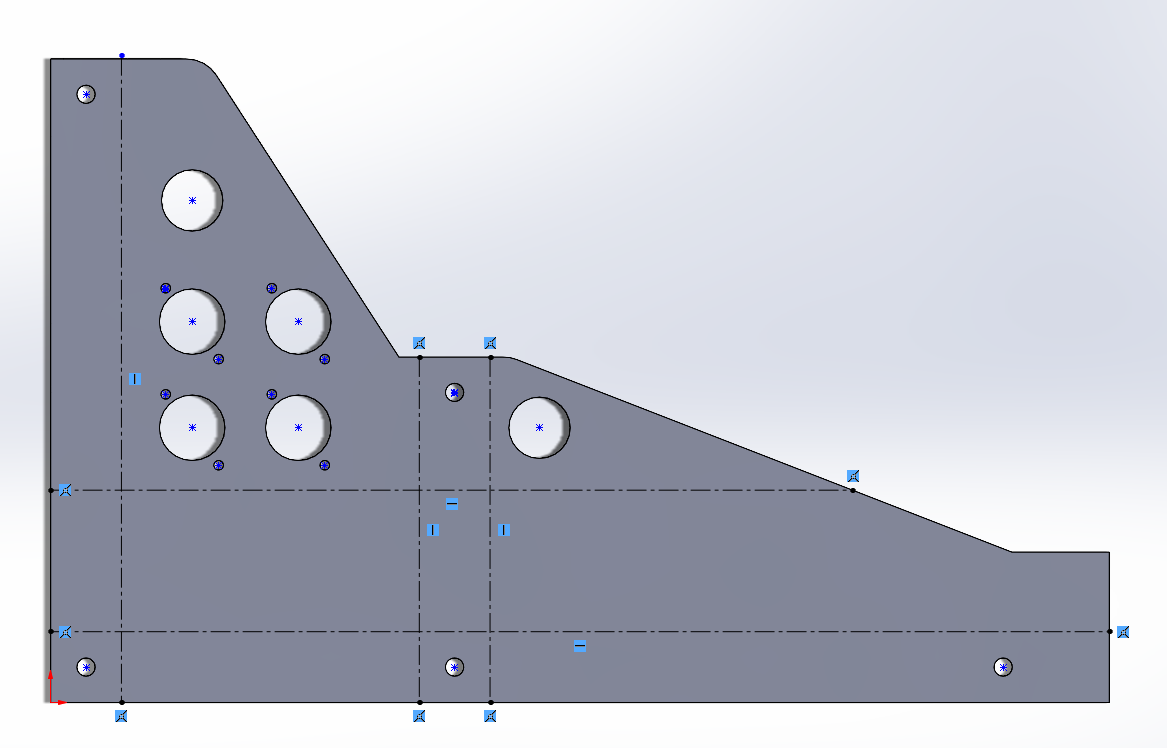

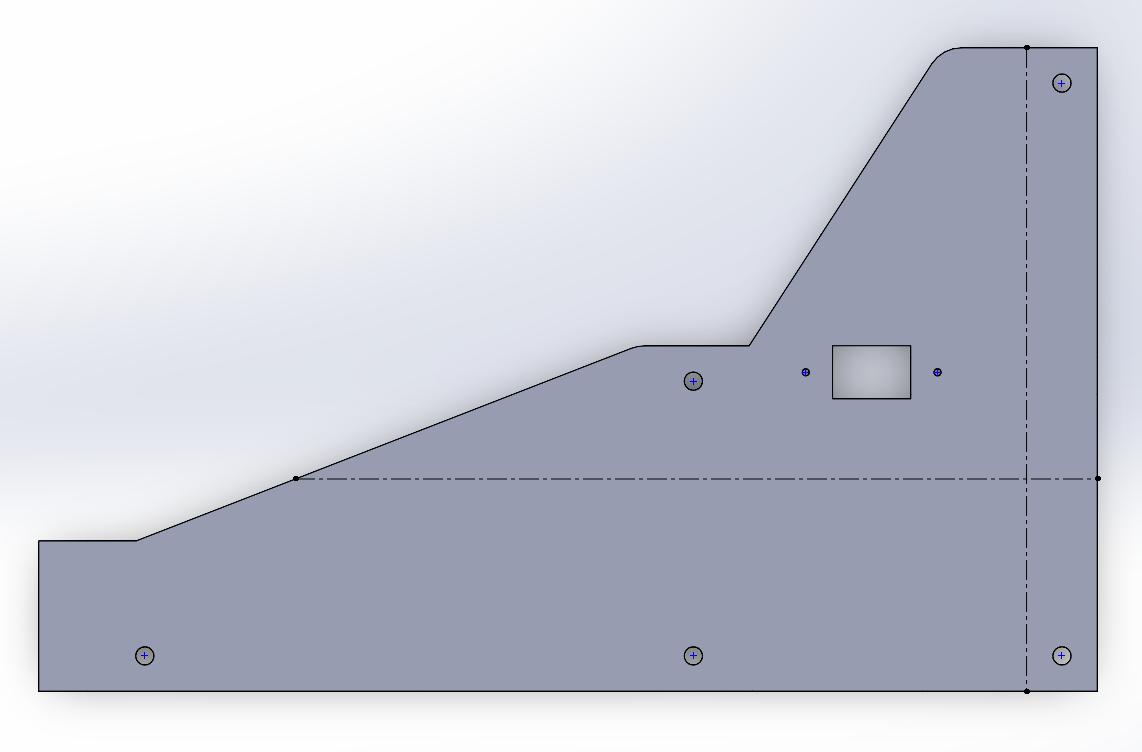

- Designed and 3D printed custom sensor mounts in SOLIDWORKS for pressure transducers, thermocouples, and solenoids integrated with National Instruments DAQ systems

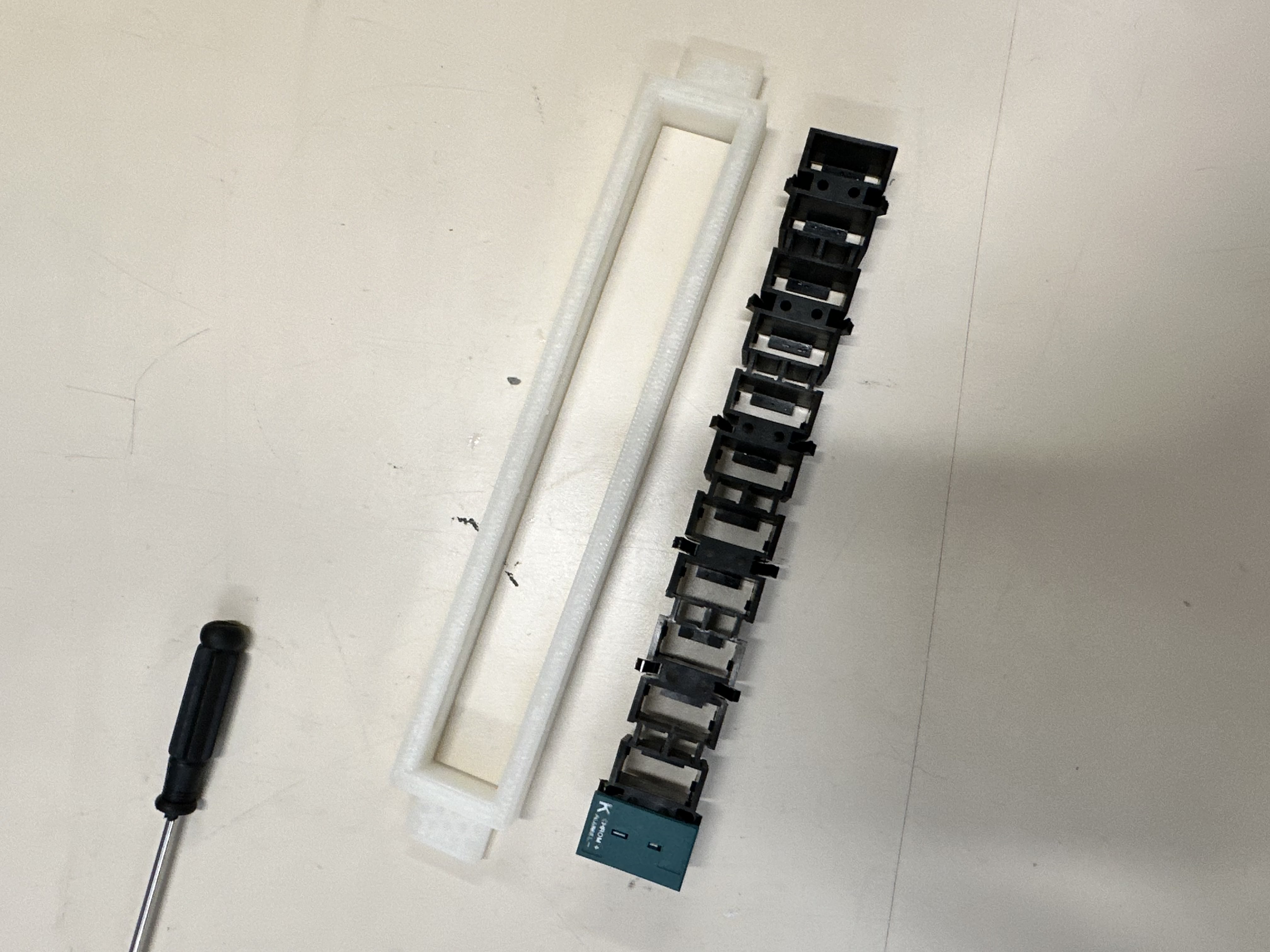

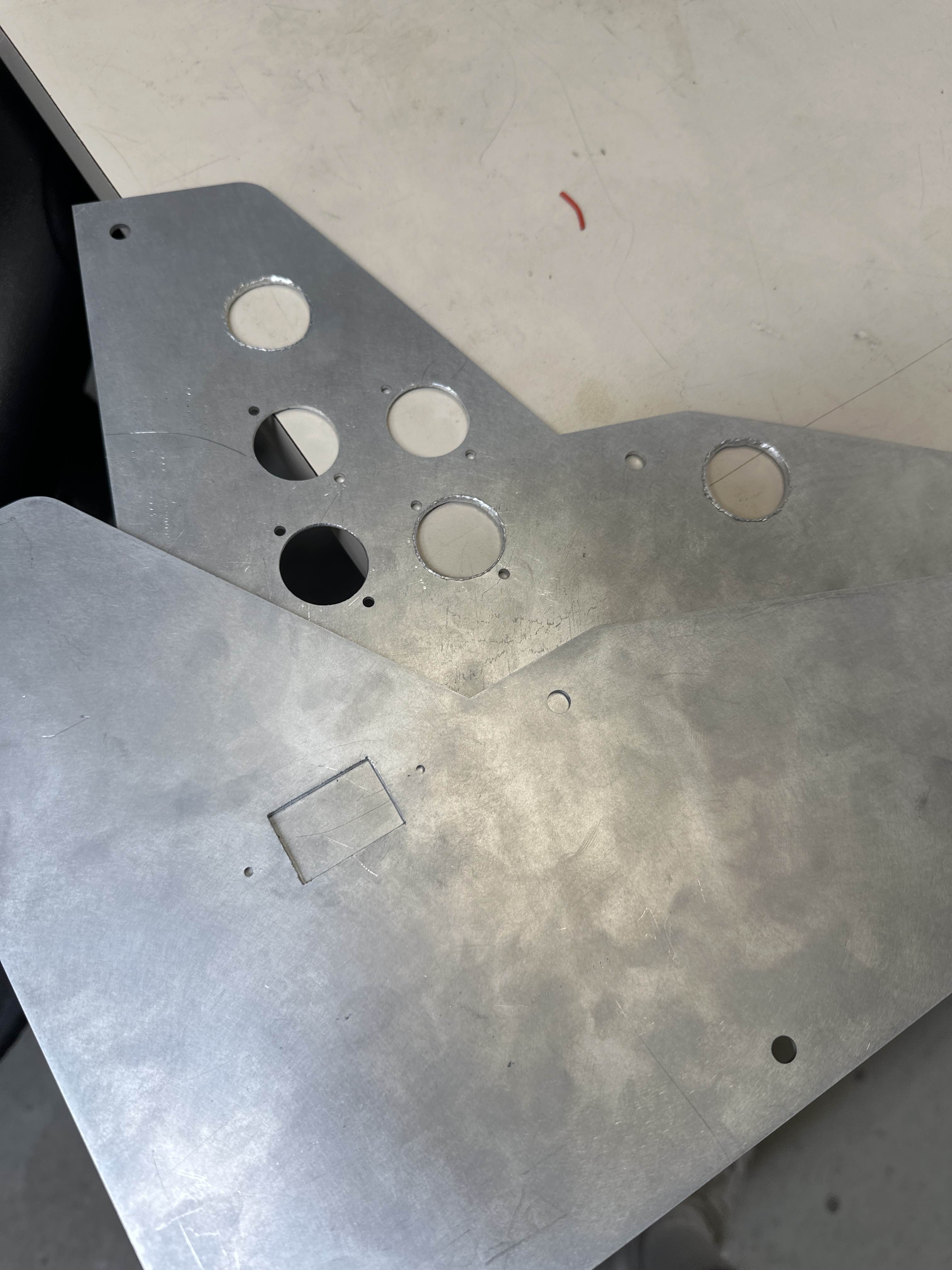

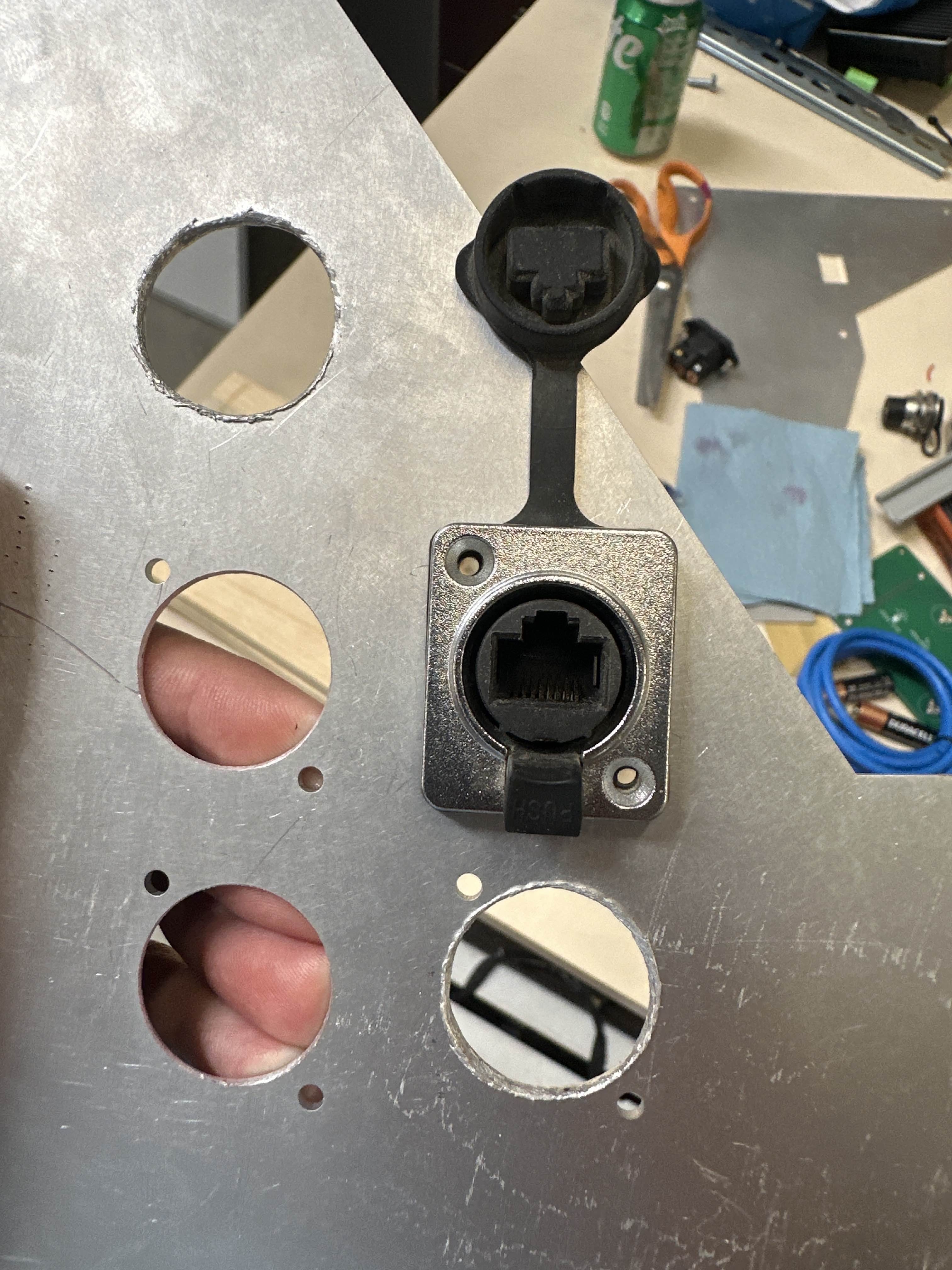

- Assembled Avionics Ground System through sensor soldering, wiring, and bulkhead panel development for sensor and power interfaces

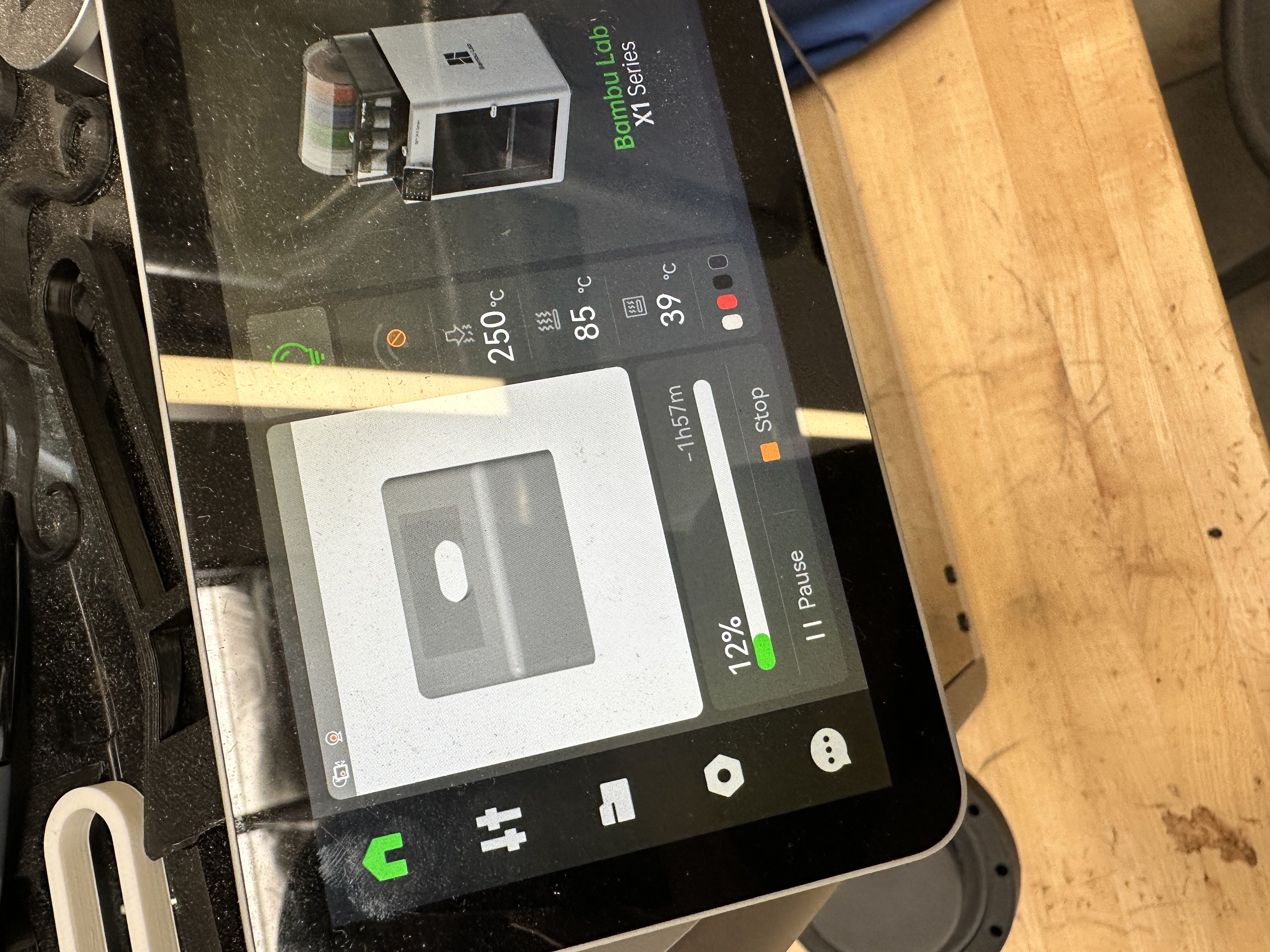

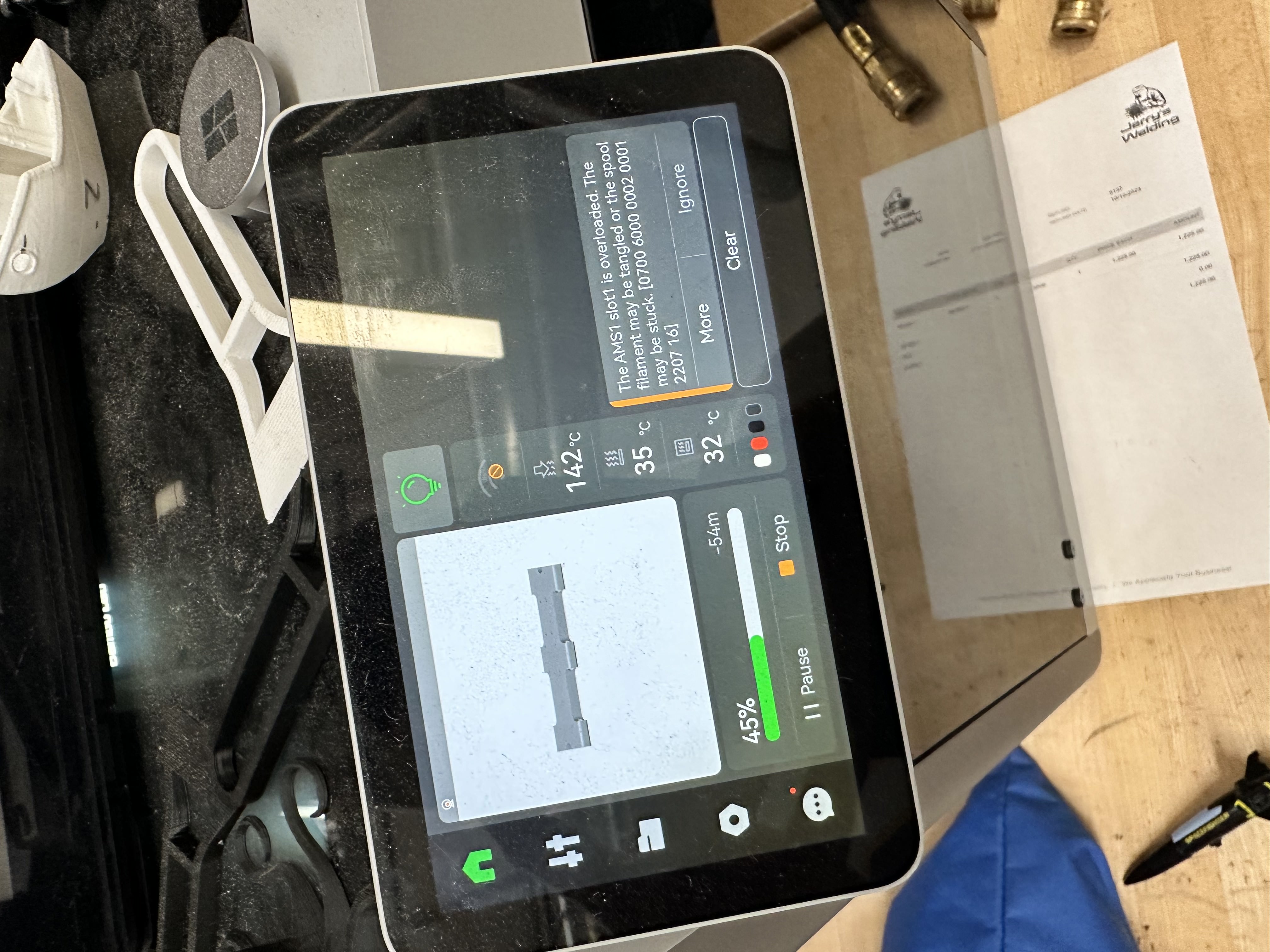

- Developed thermal-resistant hardware enclosures using ASA/PLA filaments on Bambu Lab 3D printers for electronics protection

- Researched optimal inlet-to-throat ratios for ethanol-fed Venturi flow meters in Electric Turbopump testing and prototyped Arduino-based pressure differential measurement systems

Trinity (nicknamed the Blue Box)

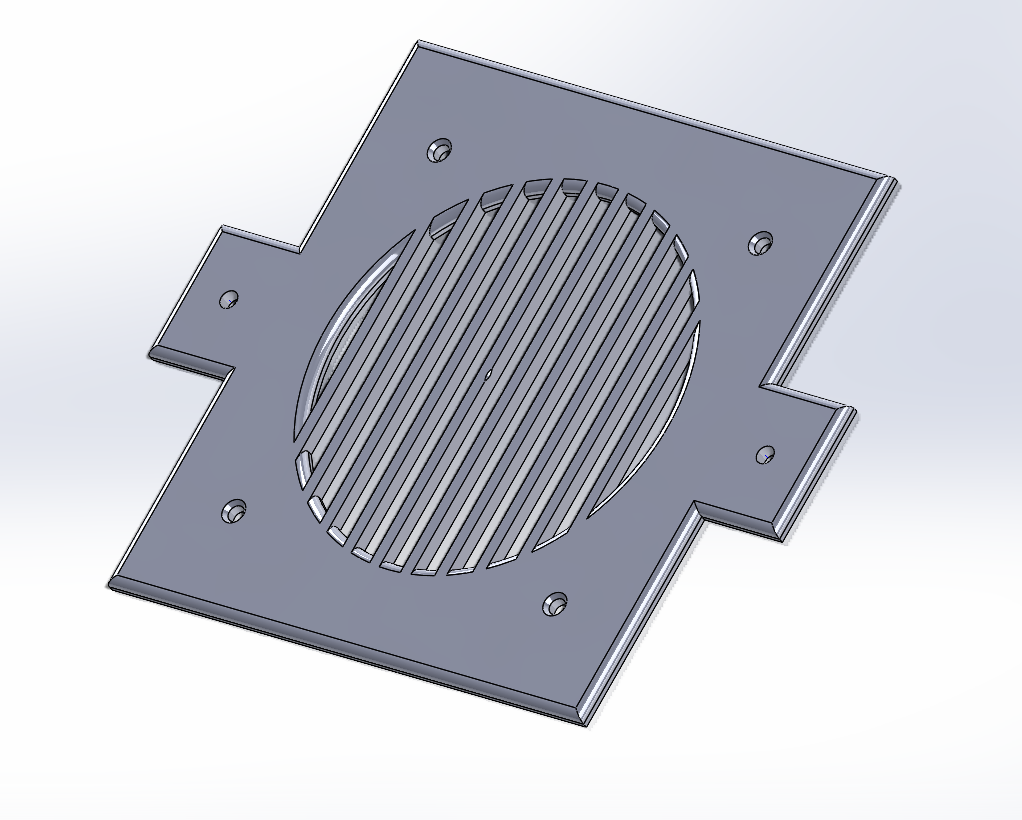

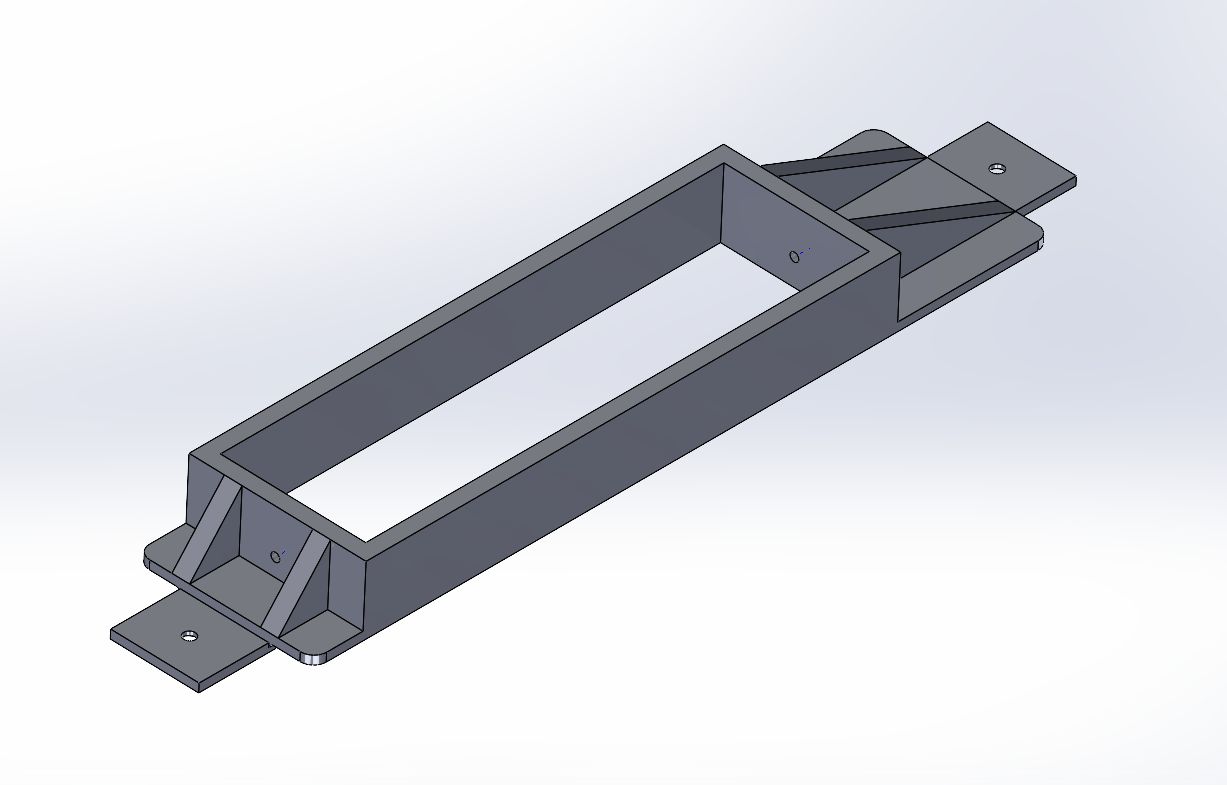

Trinity was a metallic trunk housing unit designed to protect sensitive avionics equipment during rocket launches in the heat of the Mojave desert. My role involved designing bulkhead panels and fan mounts in SOLIDWORKS, 3D printing using thermal rersistant filament for enhanced weather resistance, and sanding the old paint to replace it with thermal resistant paint. Although the project was ultimately shelved due to team changes, I gained valuable experience in CAD and additive manufacturing.

Nuclear Footlong (Portable Dual-Monitor PC)

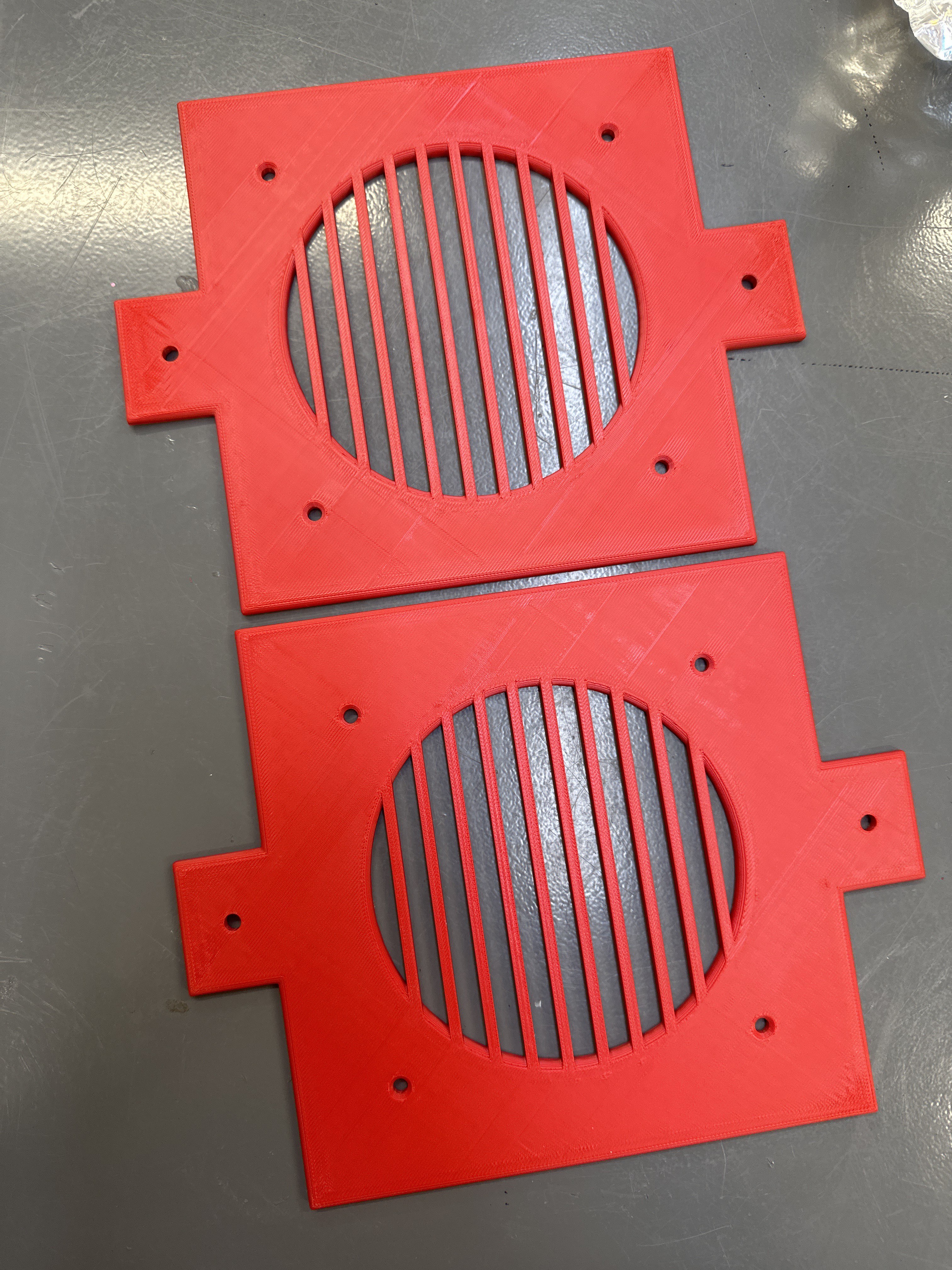

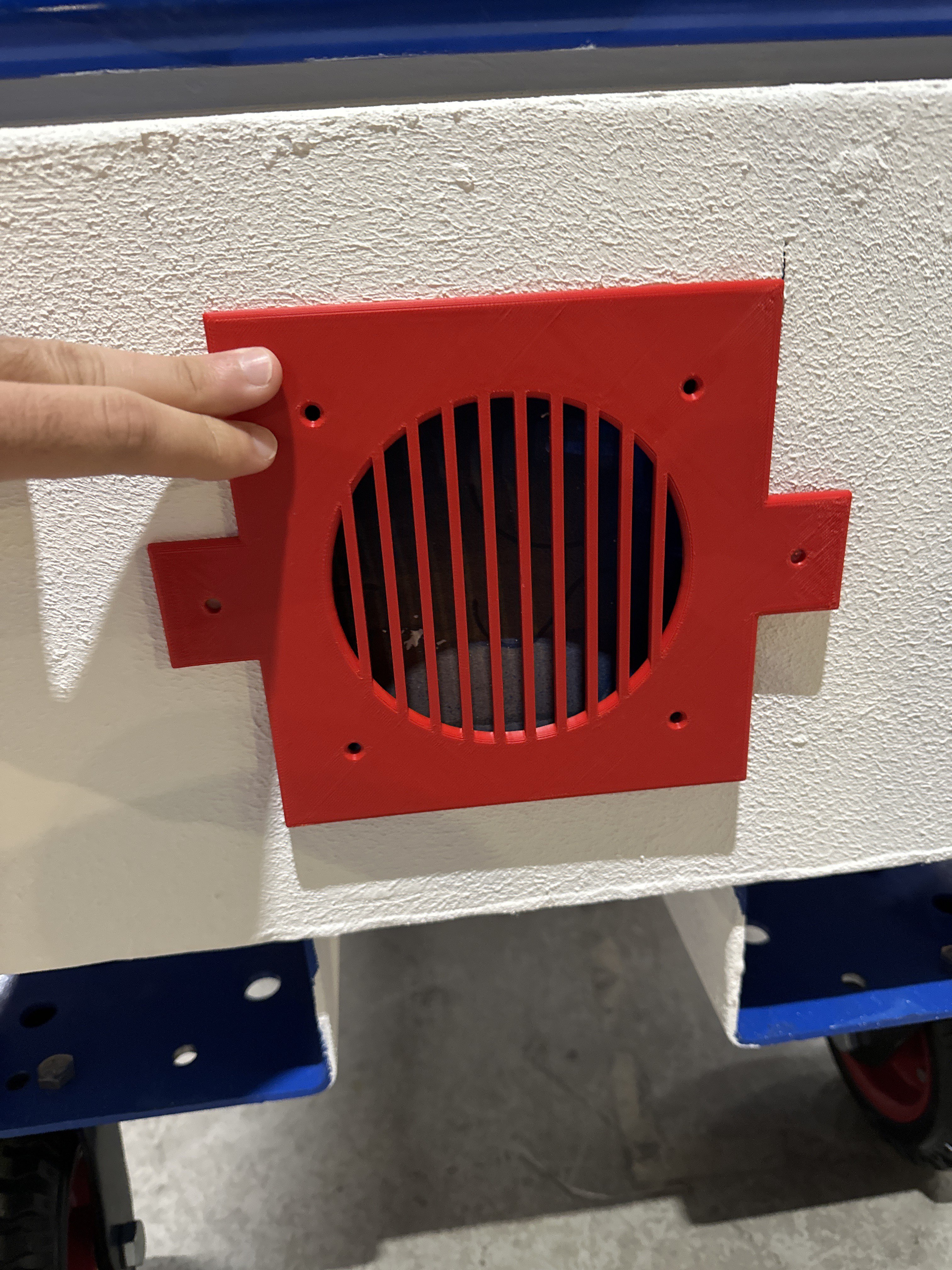

The Nuclear Footlong was a portable dual-monitor PC setup designed for field data analysis during rocket tests at the Friends of Amateur Rocketry launch-site in the Mojave desert. The project was the responsibility of Aus Isaac Al Saka, who primarily designed and built the system. My responsibilities included designing and 3D printing custom I/O panels and cooling fan mounts to ensure minimal dust entering the equipment in the desert conditions. The project was completed, but it was never used. However, I gained hands-on experience in 3D modeling, additive manufacturing, and hardware integration.

Other Work

Besides the two previously mentioned projects, I also worked on various other ground systems equipment, mainly on housing units & bulkhead interface panels design and manufacturing.

Lessons Learned

What I learned from this experience goes beyond technical skills. I learned the importance of team dynamics and communication in project success. Despite the setbacks, I gained resilience and adaptability, understanding that not all projects reach fruition, but every experience contributes to personal and professional growth.